Construction of the Monash UAV 'Duigan' Airframe

by Ray Cooper

Created and Last Updated December 8, 2002

Construction Photography - © Ray Cooper

Ray Cooper is chief pilot for the Aerobotics@Monash team. He is

also the designer and constructor of the Monash UAV 'Duigan' airframe.

Ray Cooper is chief pilot for the Aerobotics@Monash team. He is

also the designer and constructor of the Monash UAV 'Duigan' airframe.

Ray has vast experience in both fields and the Aerobotics@Monash team is very lucky indeed to have his skills and experience available for the UAV 'Duigan' project.

Below is Ray's documentation of the fuselage construction process. More images will be added soon. [Ed 081202]

Fuselage

click images to enlarge

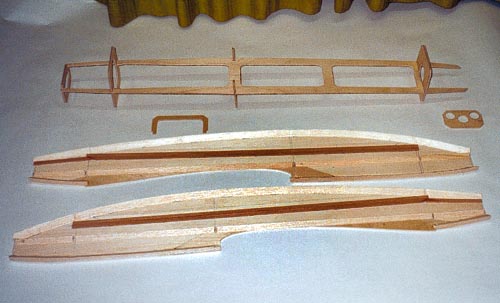

Fuselage 1: Sides and full length battery tray ready for assembly

Battery tray cut from 9 ply, sides are 3mm balsa with spruce stringers

and 12mm balsa triangles in corners for rounding

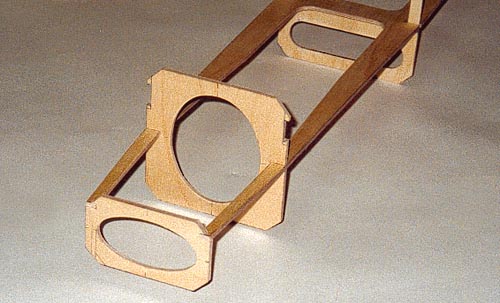

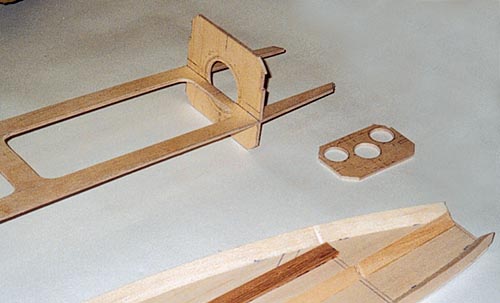

Fuselage 2 : Formers slotted into battery tray ready for sides to be glued

Fuselage 3 : Same as above, but at rear

Fuselage 4 " The pressure is on! Sides, tray, formers glued and clamped

Fuselage 5 : Top and bottom sheeting (3mm) fixed and corners rounded, canopy cut and clear PVC nose cone fitted

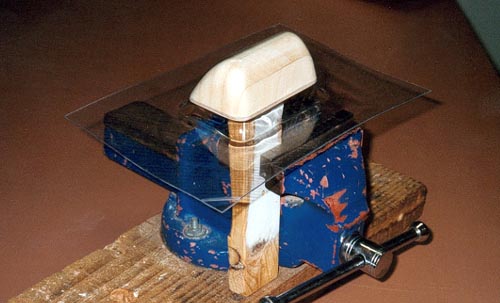

Fuselage 6 : Mould used for forming PVC nose cone. PVC is held between

2 pieces of MDF and heated in oven, when hot enough, removed from oven

and forced over mould

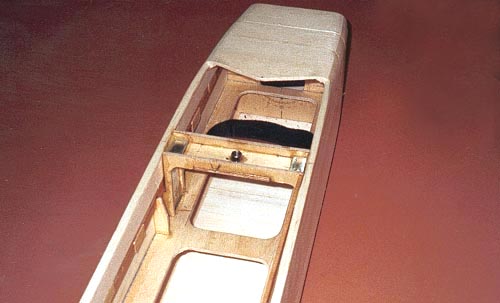

Fuselage 7 : Bracket/mount for wing retaining bolt. Battery can be slid beneath for CG adjustment

Fuselage 8 : Wing centre panel fitted to fuselage, held in place with 2 x _" Cap head screws

soon...

Centre Panel

click images to enlarge

Centre panel 1 : Foam cores ready for balsa covering. Solid black lines

are 14mm OD carbon fibre tubes, these are used for joining centre panel

to tip panels

Centre panel 2 : Foam core showing spruce spoiler bay lining. Due to torsional weakness these were later filled in

Centre panel 3 : Balsa sheeting, fibre glass, carbon fibre prepared

ready for laminating to foam core. This set up was used on all wing

panels

Centre panel 4 : L/H centre panel in vacuum bag after bonding balsa sheet to core with epoxy resin

Centre panel 5 : Centre panels ready for joining. Main rib has bolt

holes predrilled. Bent aluminium rod is glued into carbon tubes. Centre

panel joint has glass cloth bandage applied for additional strength

Tip Panel

click images to enlarge

Tip panel 1 : Ply reinforcement for Elevon servo bay

Tip panel 2 : Ply ribs fitted with blind nuts for bolting on tiplets

Tip panel 3 : L/H Tip panel in vacuum bag after bonding balsa sheet to core with epoxy resin

Tip panel 4 : Elevons cut out and faced

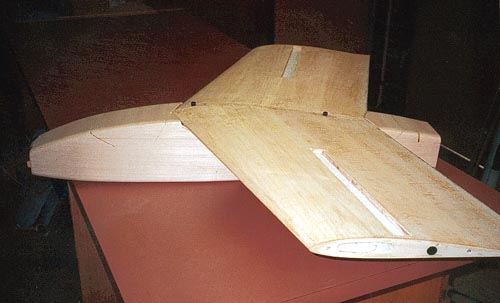

Tip panel 5 : Finished ready for outer fibre glass skins

Tip panel 6 : Tip panel jigged on workbench and covered with 3oz glass cloth

Tip panel 7 : Same as above from other end

Tip panel 8 : Electric blanket was used to keep cores warm during curing of epoxy

|  AEROBOTICS ARCHIVE

AEROBOTICS ARCHIVE AEROBOTICS ARCHIVE

AEROBOTICS ARCHIVE