We bought several AXIs around the same time early 2005 and had magnet detachment in all of them: presumably they were part of the same batch, as these motors have a good reputation.

There were a large number of similar problems reported in 2002 with high vibration in the low RPM range often accompanied by magnet detachment. Motors even in good condition have this vibration at low RPM but are otherwise smooth running at RPMs above and below this.

The problem seemed to be a combination of insufficient adhesive and flat magnets not attaching to the containment drum. The drum still had preserving lacquer on its surface and had not been abraided to aid adhesion. The fix we applied was high temperature epoxy and micro-balloons embedding the magnets. The application was aided by spinning up the assembly in a power drill! The motor still exhibited a vibration/resonance at a particular narrow RPM range.

In 2008 when flying a Giant "Zagi" Wing converted to electric the vibration problem apparently resurfaced. It may however be a failure of the motor to start cleanly as it is only overcome by shutting the throttle completely and then retrying. The noise emitted by the motor and airframe was clearly audible (very loud) 200M+ away causing other flyers at the field to do a double take.

The motor was disassembled and inspected with everything appearing to be in order and all magnets still firmly in place. The epoxy holding the magnets appeared to have taken on a barely discernable light brown tinge which is most likely dirt as the motor has had a lot of use (100s of hours) since being repaired in 2005.

On this occasion the ESC was a Titan 50A rather than the usual Hacker; the timing of the Titan ESC was set to "Auto". Further research suggested that "hard" be used as 22deg timing is specified for the AXI. I ran the AXI static with "hard" timing and the vibration effect at low throttle seems much reduced. In fact it only kicks in just short of throttle closed. Further flight tests showed that the problem had not gone away completely but seemd to be reduced.

I have yet to fly again so the inflight outcome is unknown at 31 January 2008.

In the process of building the servo loom for my relatively expensive Mini Graphite I had occasion to open up one of the wing servos. What I found filled me with dread. Quality control - what's that!

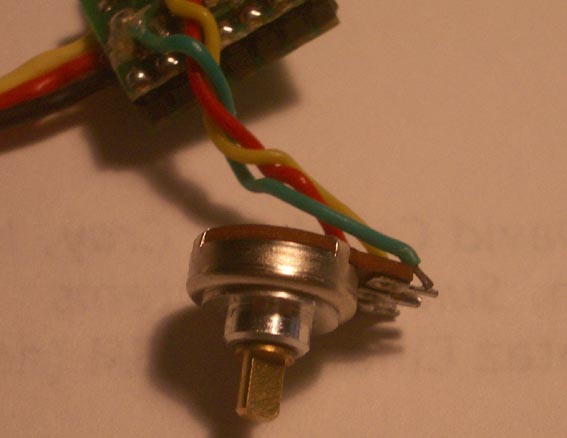

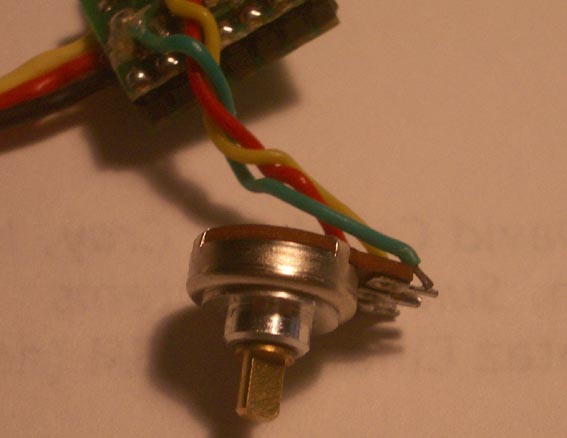

Spot the problem with this HS125 wing servo potentiometer's wiring as delivered - "Are you feeling lucky ...?"

I run a JR transmitter and the throws including throttle are set by default to 100 which does not give a 2mS output pulse. For this reason most of my ESCs have, for some time, been giving 83.3% of full throttle as I do not usually do the throttle up and down initialisation. A throw of 120 however yields 100% throttle. I discovered this on Canary which seemed a little sluggish causing me to investigate.

The motor delivered with my EPP Eagle kit, along with at least one other person's kit, had missing motor shaft circlips. Normally the magnets will hold the motor together but at maximum RPM the magnet drum can be pulled forward leading to vibration and high current which may or may not be apparent in flight. In my case the magnet drum was moving forward several millimetres when running static tests using the supplied GWS EP 8060 propellor on 3S LiPolys. The current while normal at low RPM went to ~19A at full throttle instead of the predicted 11-12A.

Missing Circlip

Approximate movement at Full Throttle

Motocalc predicts reasonable currents for the motor and at low RPM the perfomance as measured with an eMeter tracks the Motocalc predictions reasonable well; I am locating a circlip!

Copyright © G.K. & S.P. Egan - All rights reserved. Last updated March, 2016.